Technology

Main Characteristics

Simple and efficient Air Refrigeration Cycle

Developed based on the Reverse Brayton Cycle with air as the refrigerant. Air is readily available and environmentally friendly, unlike other unsafe refrigerants commonly used in the industry, which makes the system safer to maintain and contributes to reducing its environmental impact.

LNG Temperature Range

The produced LNG can be in the temperature range of -130°C to -165°C, providing flexibility to meet various operational needs.

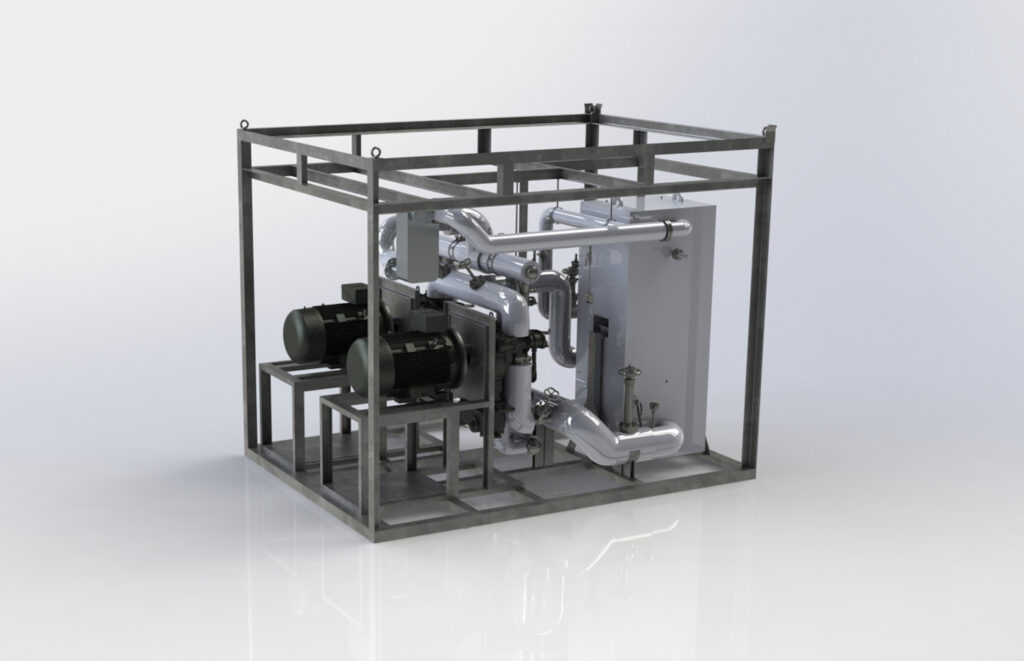

Standardization and modularity

The universal, standardized modular design is specifically tailored for various methane sources, including natural gas from the gas network, flare gas, and biogas, allowing for rapid integration into a wide range of projects.

Compact design

The compact size of 4.0 x 2.4 meters allows the module to be easily transported using standard shipping methods, while its small footprint makes it ideal for installation in space-constrained or remote locations.

Reliability and high efficiency

The simplicity of the design ensures stable operation and minimizes unscheduled maintenance, while the achieved operational efficiency is comparable to much larger productions.

Unmanned operation

Fully automated operation with advanced control systems, providing reliable and efficient performance without the need for on-site personnel.