Methane Liquefaction Module

The capital and operating costs of methane liquefaction technologies follow an exponential trend, with a critical threshold being reached as equipment capacity approaches the lower limit of 20.0 TPD of LNG. Due to this, there are only a few cryogenic equipment manufacturers offering methane liquefaction technology solutions at lower capacities, and virtually none can provide a cost-effective solution for capacities below 4.0 TPD of LNG. When attempting to implement such solutions, they face the challenge of high capital costs due to the lack of competitive component equipment on the market (such as compressors, expanders, or companders) with the low productivity required for designing an efficient refrigeration cycle.In partnership with technology companies, we have made significant progress in developing a simple, reliable, and economically efficient closed refrigeration cycle — the Methane Liquefaction Module. With the capacity to produce up to 2.5 TPD of LNG, it stands out as a unique solution without direct analogues. We call it the “Methane Liquefaction Module”.

Simple and efficient Air Refrigeration Cycle

Developed based on the Reverse Brayton Cycle with air as the refrigerant. Air is readily available and environmentally friendly, unlike other unsafe refrigerants commonly used in the industry, which makes the system safer to maintain and contributes to reducing its environmental impact.

LNG Temperature Range

The produced LNG can be in the temperature range of -130°C to -165°C, providing flexibility to meet various operational needs.

Standardization and modularity

The universal, standardized modular design is specifically tailored for various methane sources, including natural gas from the gas network, flare gas, and biogas, allowing for rapid integration into a wide range of projects.

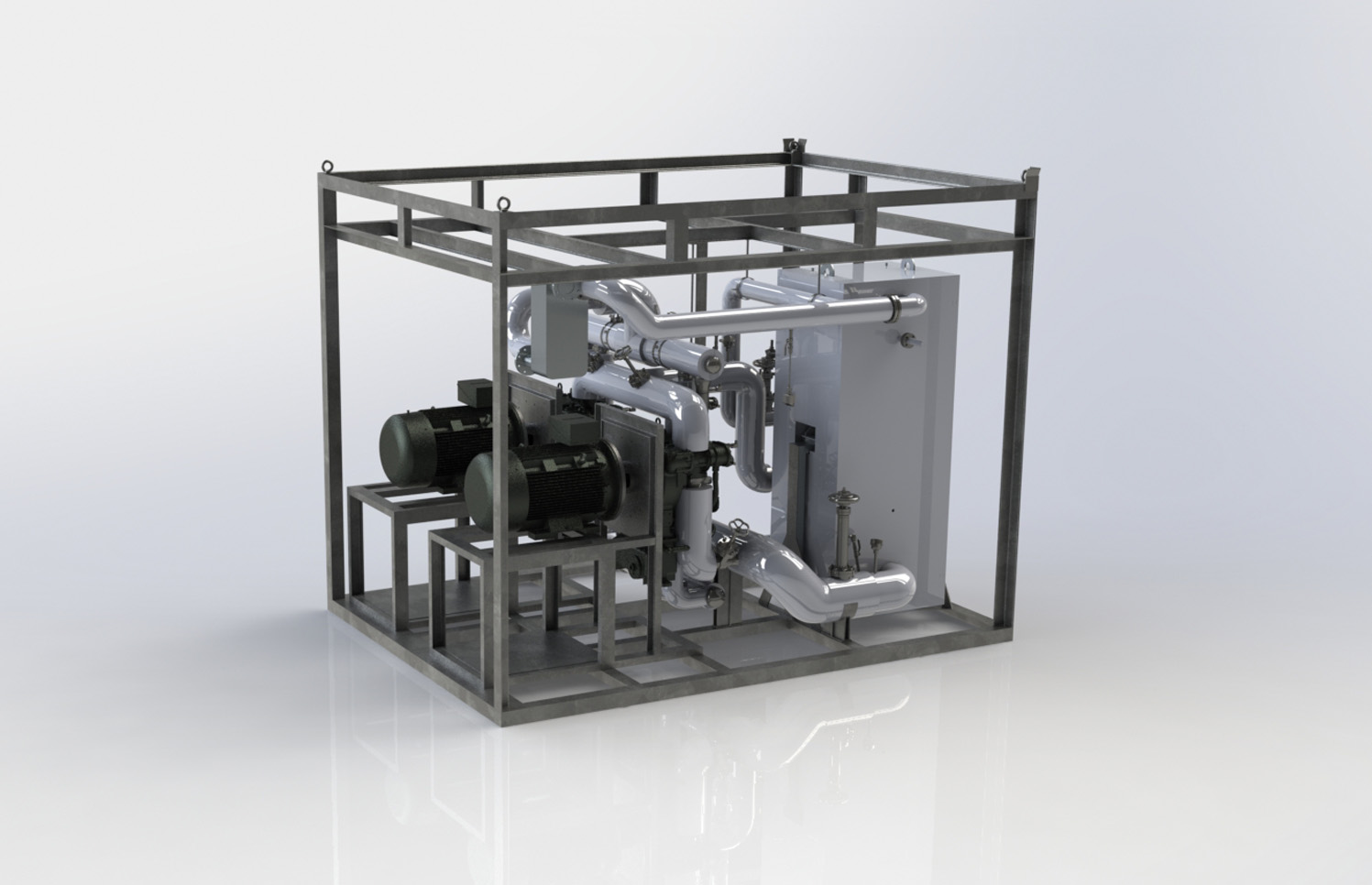

Compact design

The compact size of 4.0 x 2.4 meters allows the module to be easily transported using standard shipping methods, while its small footprint makes it ideal for installation in space-constrained or remote locations.

Reliability and high efficiency

The simplicity of the design ensures stable operation and minimizes unscheduled maintenance, while the achieved operational efficiency is comparable to much larger productions.

Unmanned operation

Fully automated operation with advanced control systems, providing reliable and efficient performance without the need for on-site personnel.

Our specialists are constantly working on improving the NANO Methane Liquefier and expanding the model range. The main priorities in this work for us were and remain increasing the reliability of the process equipment, as well as reducing capital and operating costs.In addition, we are exploring the possibility of introducing innovative solutions to optimize technological processes, to continue meeting the changing needs of the industry and customer requirements. In particular, we are partnering with the Czech Technical University in Prague to bring innovative liquefaction technology to serial production by 2026-2027.

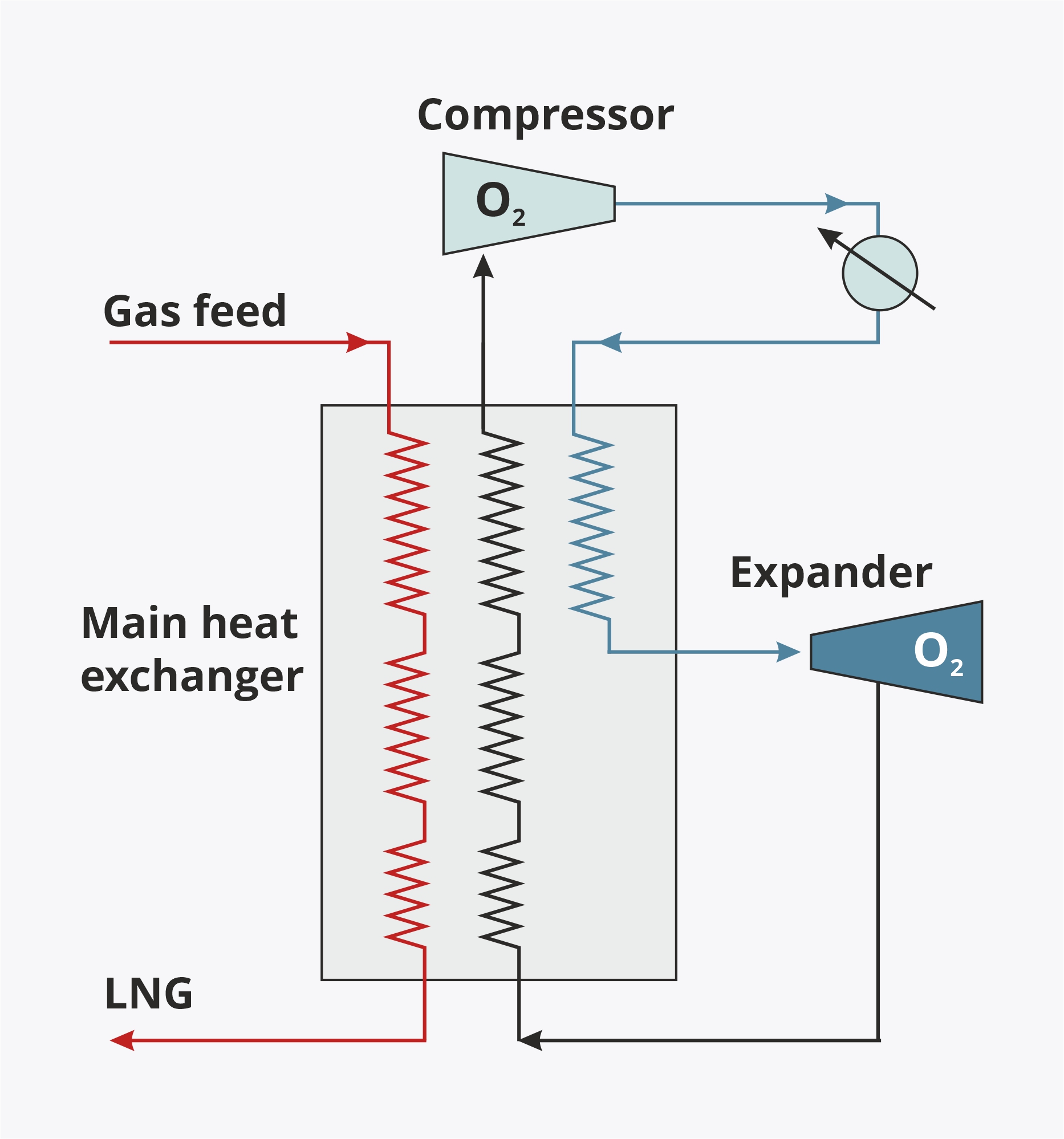

Methane Liquefaction Process

Our refrigeration cycle includes two key components: a compact and cost-efficient compander, combining two compressors and one expander, and a modern, highly efficient brazed aluminum heat exchanger (BAHX).

The cycle is based on a Reverse Brayton Cycle, using air as the working fluid. The compander, driven by a single electric motor, creates a closed cooling loop. This provides the necessary cooling capacity to liquefy high-purity biomethane, which is pre-treated in our integrated biogas purification modules.

Simple in design and fully automated, the process is highly flexible. It automatically adjusts to optimal operating conditions, producing saturated or sub-cooled liquid methane across a wide range of temperatures and pressures. This design ensures reliability and efficiency when working with diverse feedstocks while minimizing both capital and operational costs.

[elementor-template id=”2841″]