Biogas Purification & Liquefaction Plant

Unit capacity

Biogas (50% CH₄)

320 Sm3/h

Biomethane

160 Sm3/h

BioLNG

110 kg/h 2.65 TPD

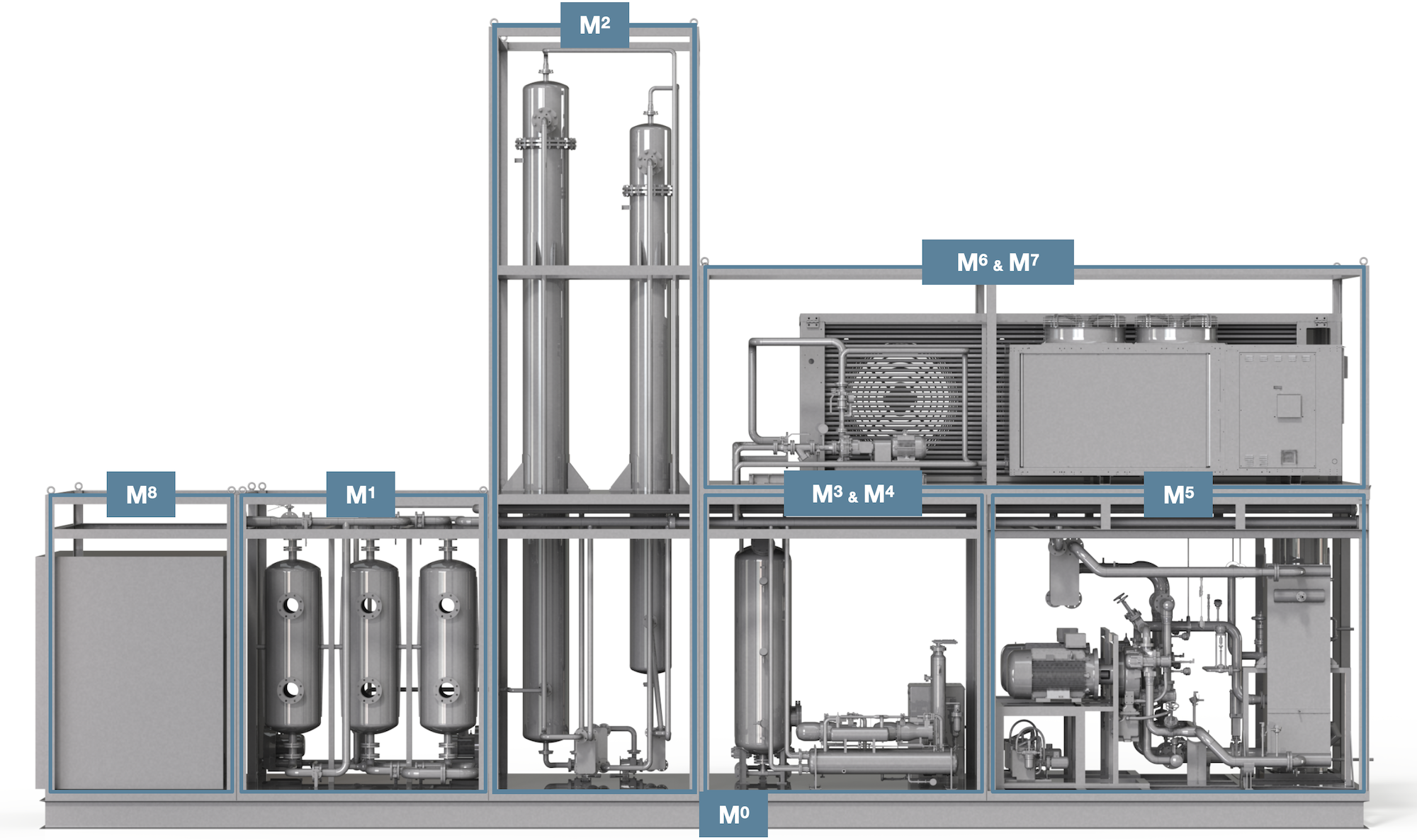

M0 – Frame

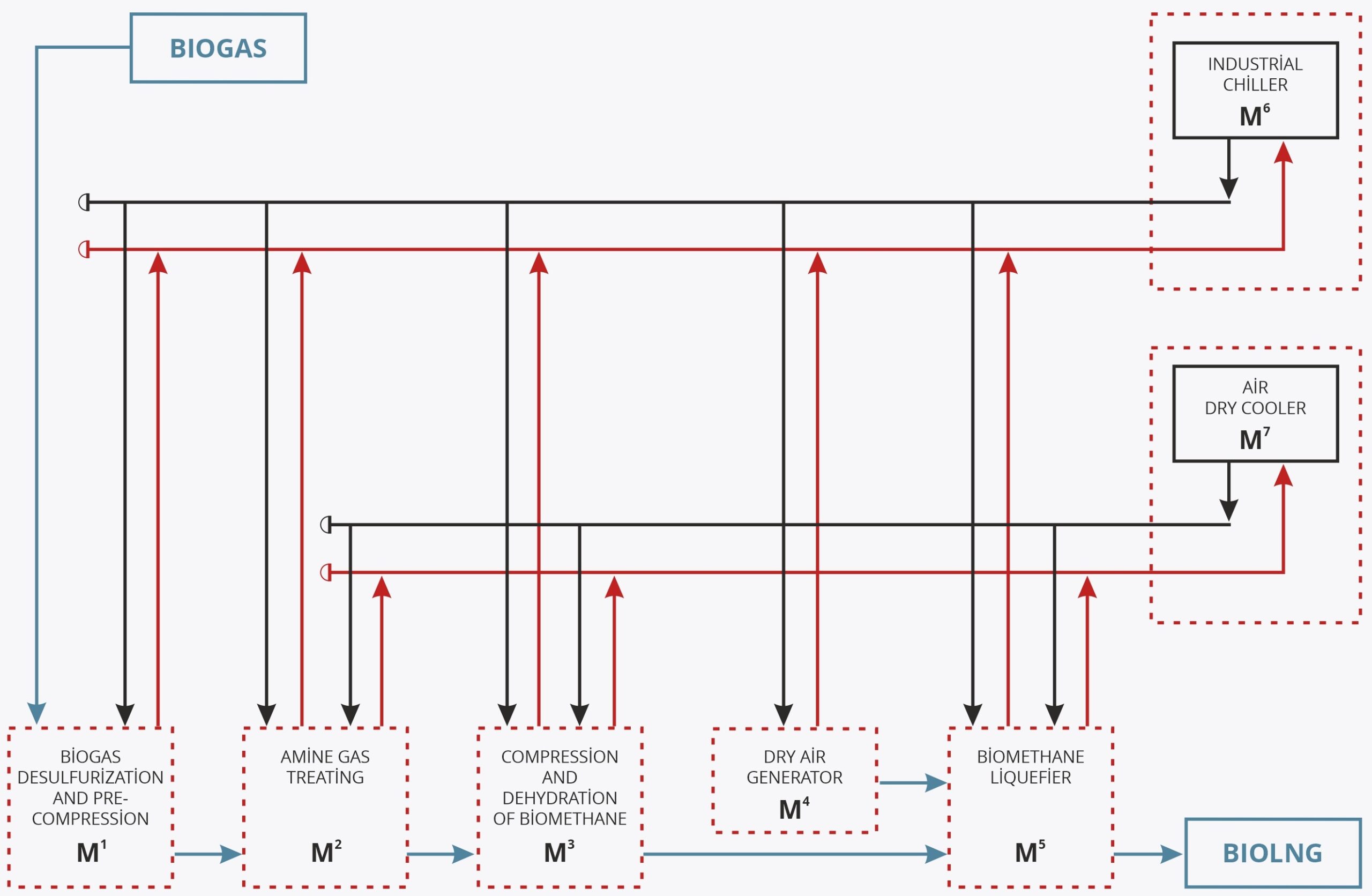

PROCESS #1: Processing biogas into high-purity biomethane

Removal of all components H₂S, VOCs, CO₂ & H₂O from biogas to obtain highly purified biomethane (LNG spec).

M1 - Biogas desulfurization and pre-compression

M2 - Amine gas treating

M3 - Compression and dehydration of biomethane

PROCESS #2: Biomethane liquefaction

The biomethane is liquefied in a Brazed Aluminum Heat Exchanger using a Reverse Brayton Cycle in which dry air is compressed and expanded down to -165°C.

M5 - Biomethane liquefier

PROCESS #3: Central services

The biomethane is liquefied in a Brazed Aluminum Heat Exchanger using a Reverse Brayton Cycle in which dry air is compressed and expanded down to -165°C.

M4 - Dry air generator

M6 - Industrial Chiller

M7 - Air Dry cooler (Adiabatic Cooler for hot country)

M8 - Power and control room

Modular Design

All stages of the process—gas purification, drying, and liquefaction—are integrated into eight compact modules assembled in a Plug & Play format.

Compact Size

All technological equipment is housed on a platform with dimensions of 14.0 m (length) x 2.9 m (width) x 9.5 m (height).

Operational Flexibility

The system is designed to handle biogas of various compositions, including gas with high CO₂ and H₂S content. It can also be customized to meet specific technical requirements.

High Automation

The fully automated system eliminates the need for constant operator presence, significantly reducing operational costs.

Eco-Friendliness

The plant employs an air-based cryogenic cycle, which is safe for the environment and free of chemical refrigerants

General cooling system

Non-Critical Processes

Critical Processes

Technology

Methane

Methane Separation, purification and liquefaction of small volumes of methane Methane (CH₄) is the simplest saturated hydrocarbon in composition. The abundance of methane on Earth

Carbon Dioxide

Carbon Dioxide Carbon dioxide (CO₂) — under normal conditions, it is a colorless gas that has virtually no odor. It can take the form of

Cryogenic Preservation

Our focus is on the development of sophisticated automation for the cryogenic processing and storage of high-quality, biological food products, ensuring freshness and extending shelf