Cryogenic Preservation

Freezing Technology

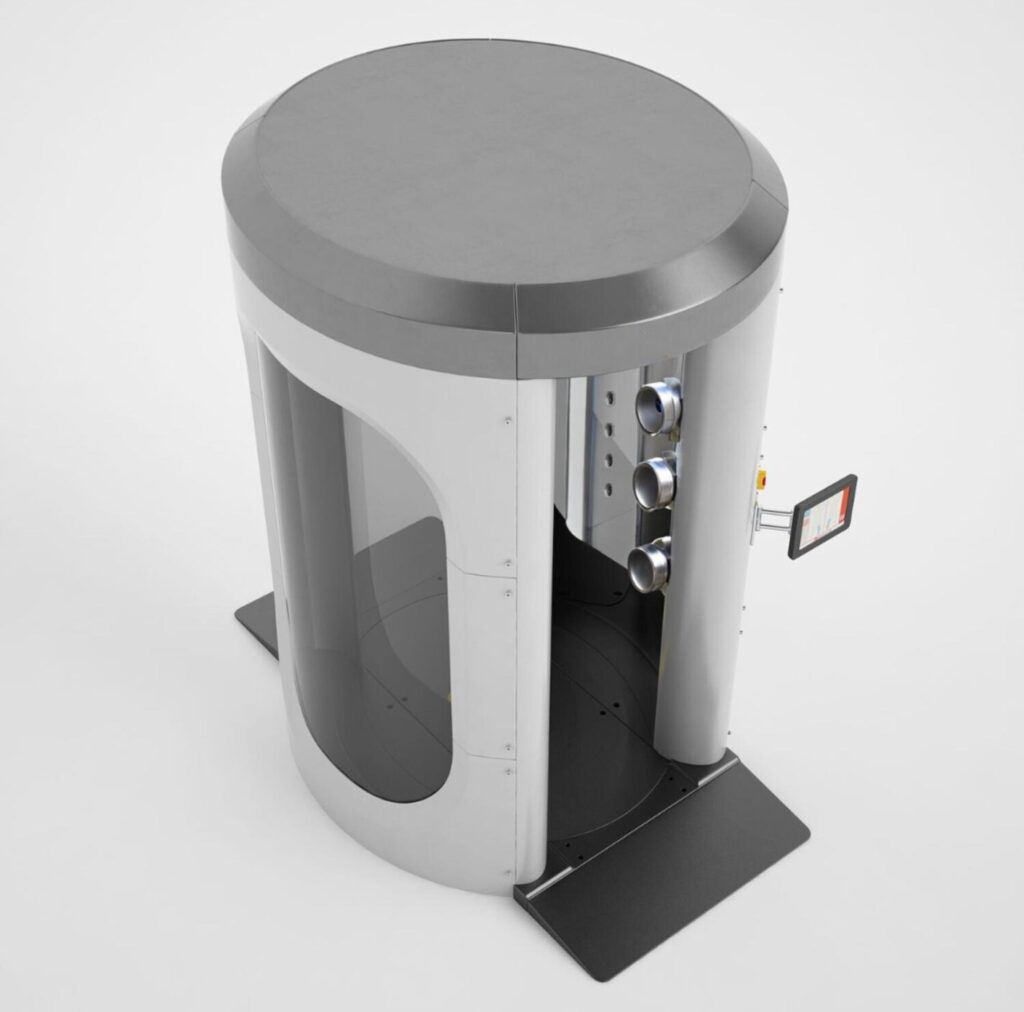

We utilize cutting edge freezing technology to rapidly freeze food, preserving texture, taste, and nutritional value with unparalleled efficiency. Rounding out our comprehensive system a machine, which delivers ultra-low temperatures down to -160°C for sterilization and storage. This technology ensures the highest standards of food safety and extended shelf life for all products.

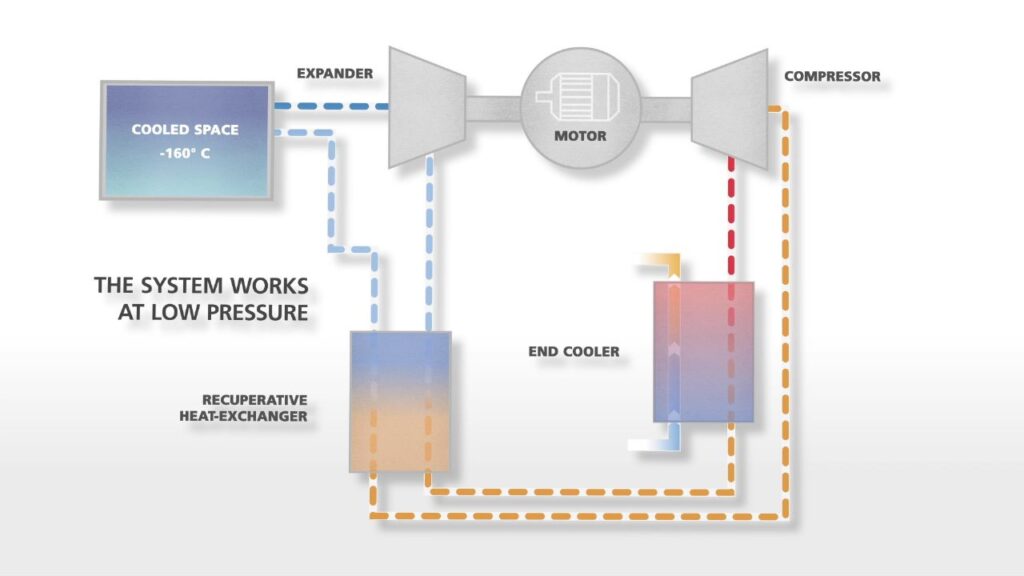

The air cycle

The air cycle is widely used in air separation plants as a cooling stage to obtain cryogenic cold, to liquify natural gas, as well as in an aircraft air conditioning systems.

The heart of the system is turbo-module unit developed and manufactured in-house for the most efficient and reliable work. The technology is based on the heating capability of air during compression and cooling down during expansion. Repetition of compression and expansion cycles allows to reach and maintain ultra-low temperatures down to -160 °C.

Information system

Complementing this, Vema Carbon's cloud-based information system serves as a central hub for real-time product data, aiding logistics and inventory management in the modern, data-centric economy. The system tracks products through the supply chain and features advanced analytics for strategic decision-making. Read more

Global Sourcing for Advanced Equipment

Our commitment to excellence is reflected in our sourcing strategy. By collaborating with premier suppliers from around the globe we ensure that each component of our cryogenic complexes is of the highest quality. Our global network allows us to integrate the best scanning, freezing, and storage technologies into a harmonious system that sets a new industry standard. Our rigorous selection process for suppliers means that we not only look for quality but also for sustainability and innovation in their practices, ensuring our operations contribute positively to the environment and stay ahead of technological advances.

Scanning Technology Integration

Vema Carbon is revolutionizing meat and seafood quality assessment with its Quality Assessment Innovation initiative, shifting from subjective evaluations to an objective, data-driven system. This innovation includes a suite of quantitative characteristics integrated into a mathematical model. The approach leverages advanced algorithms and machine learning to measure a broad spectrum of meat qualities, leading to a consistent and reliable quality rating crucial for informed decision-making in the industry.

Tailored Excellence in Food Preservation

Vema Carbon takes pride in offering custom-designed cryogenic processing complexes to meet the specific needs of our clients.

The scanning, freezing, and storage technologies are housed in a coherent, modular setup that emphasizes efficiency and ease of use and are capable of accommodating a wide spectrum of production demands, ranging

from

500 kg of product per day to a robust 10 tonnes per hour.

Understanding that each type of food product requires a unique approach to preservation, we work closely with our clients to design a system that addresses their particular challenges and demands. Our bespoke solutions ensure that whether you’re dealing with tender organic meats or the delicate textures of fine seafood, your products retain their premium quality.

Our design philosophy focuses on creating a unified complex where each component works in concert.